Cinilex DPP Red SR2P

The formulation of cost effective and high performance red shades for plastic applications is now made easier with Cinilex DPP Red SR2P. Its selection provides colorists with the opportunity to use a reduced organic red pigment portfolio through standardization, replacing other organic red and Molydbdate pigments, whilst providing outstanding performance, such as heat, light, weather and migration resistance and satisfying all of today's stringent regulatory requirements. When faced with the challenge of a red formulation, choose Cinilex DPP Red SR2P - a true standard red pigment for the plastics industry.

-

C. l. NamePigment Red 254

-

C. I. No.56110

-

CAS No.84632-65-5

-

Chemical ClassDiketo-pyrrolo-pyrrole

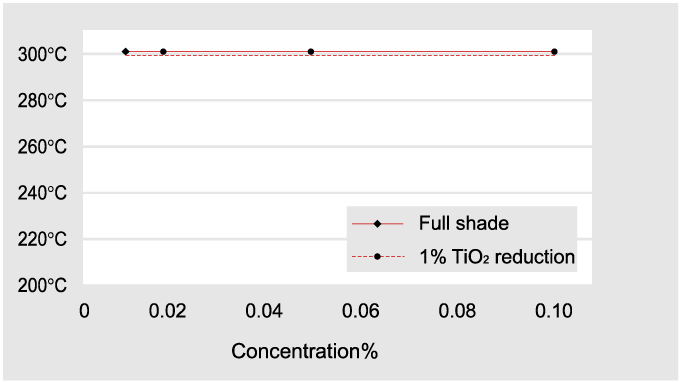

Full shade in PP (0.1%)

1/3 ISD in PP (0.19%+1% TiO2)

-

Physical Data

-

Regulatory Compliance

-

Heat Resistance in HDPE

-

Warping

-

Fastness Properties

-

Applications

| Density (g/cm3) | 1.59 |

| Specific surface (m2/g) | 26.9 |

| DOP absorption (g/100g) | 49.9 |

| Hydrochloric acid resistance | 5 |

| Sodium hydroxide resistance | 5 |

| FDA | √ |

| APME AP 89/1 | √ |

| CONEG, EC 94/62 | √ |

| EN 1122 | √ |

| EPA 3050B | √ |

| EN 71-3, 2013 | √ |

| JOHSPA | √ |

| JHPA | √ |

| GB9685-2008 | √ |

|

| - | - |

| PVC | ● |

| LDPE | ● |

| HDPE/PP/PP Fibre | ● |

| PS | ● |

| PUR | ● |

| ABS | ○ |

| PA-6 | — |

| PA-66 | — |

| PC | — |

| PET/PBT | — |

| POM | ● |

| Rubber | ● |

| ● recommended ○ potential use — not recommended | |